Contents

Introduction

Why Maintenance Is Crucial for Plastic Crusher Machines

Regular Cleaning to Prevent Blockages

Lubrication for Smooth Operation

Monitor and Replace Worn-Out Parts

Proper Adjustment of Blades and Screens

Maintain Optimal Electrical and Motor Systems

Conclusion

FAQ

Introduction

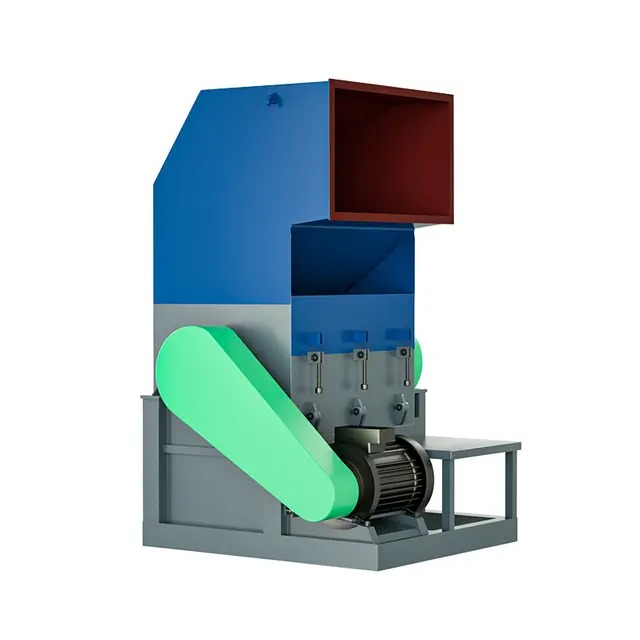

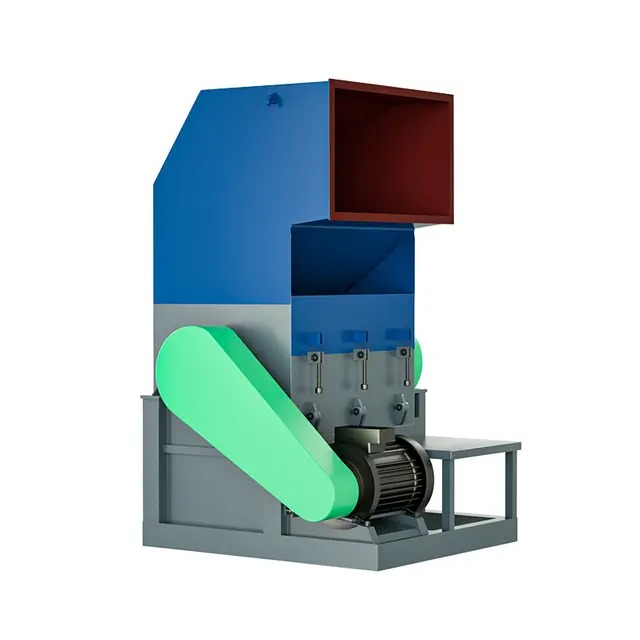

Plastic crusher machines play a pivotal role in modern recycling processes, particularly in industrial applications. These machines are designed to break down plastics into smaller, manageable pieces, facilitating their reuse in manufacturing and reducing environmental waste. However, to ensure longevity, efficiency, and optimal performance, regular maintenance of plastic crusher machines is essential.

Failure to maintain these machines not only reduces their operational lifespan but also results in costly repairs and downtime. In this blog, we’ll explore five key maintenance practices that are essential for maximizing the effectiveness and longevity of your Plastic Crusher Machine.

Why Maintenance Is Crucial for Plastic Crusher Machines

Plastic crusher machines, especially those like the High-efficiency Plastic Crusher Machine and Industrial Plastic Crusher Machine for Recycling, are integral to high-capacity recycling operations. These machines process a variety of materials, including hard plastics, PET bottles, and industrial waste, which often contain contaminants or are subject to wear and tear.

Regular maintenance is vital for several reasons:

Prevents Downtime: Routine maintenance keeps your machine operating without interruptions, ensuring consistent production.

Optimizes Performance: A well-maintained Plastic Crusher Machine operates more efficiently, reducing energy consumption and increasing processing speed.

Increases Longevity: Regular care helps preserve the integrity of the machine, reducing the need for costly repairs or part replacements.

Enhances Safety: Proper maintenance ensures that the machine runs safely, minimizing the risk of accidents or malfunctions.

Let’s dive into the five key maintenance methods for Plastic Crusher Machines that will keep your equipment running at peak performance.

Regular Cleaning to Prevent Blockages

A clean plastic crusher is essential for optimal operation. Over time, plastic waste and debris can build up in various parts of the machine, leading to clogs that interfere with the crushing process. This can not only reduce the efficiency of the Plastic Crusher Machine for PET Bottles but also lead to unnecessary wear on its components.

Steps for Regular Cleaning:

Daily Cleaning: Remove plastic residues and debris from the machine after each operating cycle to avoid buildup.

Check for Blockages: Ensure that the hopper, crushing chamber, and discharge areas are clear of material obstructions.

Clean the Screen: Periodically clean the screen or filter mesh to maintain airflow and ensure that plastic waste is properly processed.

By dedicating time to regular cleaning, you ensure that the machine runs smoothly and can handle large volumes of material, improving the overall efficiency of operations.

Lubrication for Smooth Operation

Lubrication is a vital maintenance activity for any mechanical machine, including the High Capacity Plastic Crusher Machine. Proper lubrication of moving parts reduces friction and wear, which helps in extending the lifespan of critical components like the motor, gearbox, and bearings.

Benefits of Proper Lubrication:

Reduces Wear: Lubricating the moving parts helps prevent metal-to-metal contact, which can cause damage and premature failure.

Improves Efficiency: Well-lubricated components experience less friction, reducing energy consumption and heat generation.

Prevents Overheating: Lubrication helps to dissipate heat, keeping the machine from overheating during extended periods of operation.

Recommended Lubrication Schedule:

| Component | Lubrication Interval | Type of Lubricant |

| Bearings | Every 500 hours of operation | High-quality grease |

| Gearbox | Every 1000 hours of operation | Synthetic gear oil |

| Blades and shafts | Every 200 hours of operation | Anti-wear oil |

By sticking to a regular lubrication schedule, you’ll ensure the smooth and efficient running of the machine while avoiding costly downtime.

Monitor and Replace Worn-Out Parts

Plastic crusher machines have various components that experience wear and tear over time. These parts include blades, screens, gears, and the motor, all of which are crucial for the machine’s performance. Monitoring the condition of these parts and replacing them when necessary is critical to maintaining the Plastic Crusher Machine for Hard Plastic Recycling.

Commonly Worn Parts:

Blades: The blades are the most critical components for crushing plastic. Over time, they can become dull or damaged, affecting their ability to process materials efficiently.

Screens: The screens are essential for sorting materials by size. They can wear out or become clogged, causing inefficiencies in the crushing process.

Belts and Motors: The power components can wear down, reducing the machine’s capacity and energy efficiency.

Replacement Tips:

Inspect Parts Regularly: Conduct visual inspections to spot early signs of wear or damage.

Replace Parts Promptly: If a component shows signs of severe wear, replace it immediately to avoid affecting the overall machine performance.

Source Quality Replacements: Always opt for OEM (Original Equipment Manufacturer) parts to ensure compatibility and performance.

Regular inspection and timely replacement of worn-out parts will ensure your Low Energy Consumption Plastic Crusher Machine runs at peak efficiency.

Proper Adjustment of Blades and Screens

The adjustment of the blades and screens in a plastic crusher machine is one of the most important aspects of maintenance. Blades that are too tight or too loose can cause poor performance, while improperly set screens can affect the particle size of the processed material. Ensuring proper adjustments can help maintain a high level of operational efficiency.

How to Adjust Blades and Screens:

Check Blade Sharpness: Ensure that the blades are sharp enough to process plastic waste efficiently. Dull blades require more power, leading to higher energy consumption and reduced crushing efficiency.

Blade Alignment: Proper alignment of the blades ensures uniform crushing, reducing the strain on the motor and preventing unnecessary wear.

Screen Settings: The screen should be set to an optimal mesh size to ensure the appropriate separation of materials, improving the quality of the crushed plastic.

Regular adjustments will help in achieving better performance, prolonging the life of the Plastic Crusher Machine and ensuring lower energy consumption.

Maintain Optimal Electrical and Motor Systems

The electrical and motor systems in a plastic crusher machine are key to its functionality. A malfunctioning motor or electrical issue can halt operations and lead to costly repairs. Properly maintaining these systems ensures that the High-efficiency Plastic Crusher Machine operates smoothly, reducing energy consumption and enhancing productivity.

Electrical System Maintenance:

Check Wiring: Inspect wiring for any signs of wear or loose connections that could cause electrical malfunctions.

Monitor Voltage: Ensure the machine is receiving the correct voltage to prevent overloads and reduce the risk of motor burnout.

Clean Electrical Components: Dust and debris can accumulate on electrical components, leading to overheating. Clean components regularly to prevent this.

Motor Maintenance:

Lubricate Bearings: Motor bearings need regular lubrication to prevent excessive wear and maintain smooth operation.

Inspect for Overheating: Ensure that the motor isn’t overheating, as this could indicate a problem with ventilation or excessive strain.

By ensuring the electrical and motor systems are well-maintained, you guarantee that the Plastic Crusher Machine operates with minimal disruption and maximum energy efficiency.

Conclusion

Maintaining a Plastic Crusher Machine is an essential task for ensuring its efficiency, reducing downtime, and extending its lifespan. By implementing the five key maintenance strategies outlined above—regular cleaning, lubrication, monitoring and replacing worn parts, proper blade and screen adjustments, and maintaining electrical and motor systems—you can significantly improve the performance of your machine. This will lead to lower energy consumption, higher capacity, and increased productivity in your plastic recycling processes.

Remember, a well-maintained machine not only saves you money on repairs but also helps in achieving more sustainable recycling practices, contributing to a cleaner environment.

FAQ

1. How often should I clean my Plastic Crusher Machine?

You should clean the machine after every operational cycle to prevent material buildup and potential blockages.

2. Can I use any lubricant for the crusher machine?

No, always use lubricants recommended by the manufacturer to ensure compatibility and optimal performance.

3. How can I tell if the blades need to be replaced?

If the blades are visibly dull, chipped, or not processing materials efficiently, it's time for a replacement.

4. What is the ideal maintenance schedule for my machine?

The ideal maintenance schedule depends on usage, but regular inspections every 200 to 500 hours of operation are recommended.

5. Is it safe to operate the machine without proper maintenance?

No, neglecting maintenance can lead to safety hazards, reduced machine efficiency, and premature failure of critical components. Always follow a routine maintenance plan.