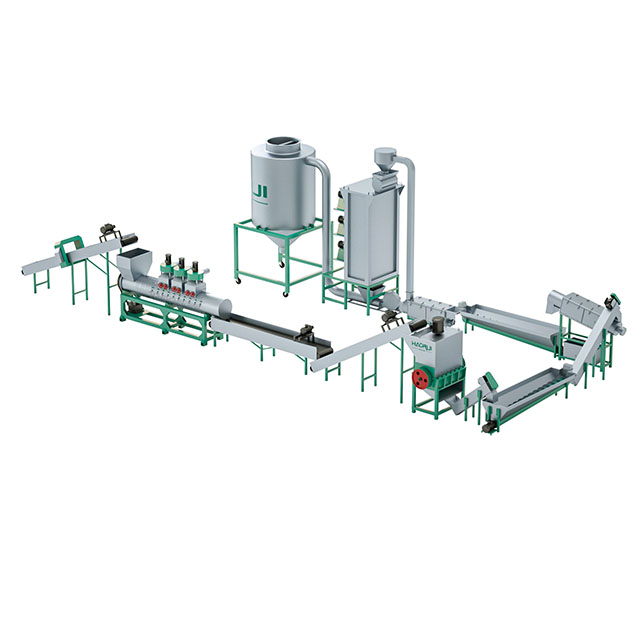

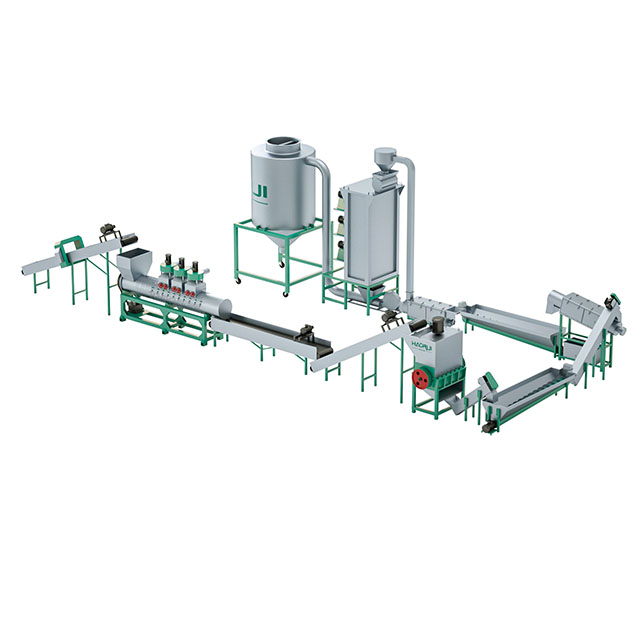

Automatic 2000kg/h Plastic Recycling Equipment Food Grade B2B PET Bottle Washing Line

Product Description:

Haorui food grade pet bottle washing recycling line consist of a series of equipment including Trommer, Pre-washer, Bale Opener, Dewatering Machine, Floating Washing Tank, Hot Air Dryer, Frication Washer, Label Separator, Label Remover, Hot Washing Tank,including the complete process components like sorting → crushing → washing → drying.It has a function of making recycle plastic granules.This pet bottle washing recycling line can be operated automatically efficiently,reducing downtime and improving productivity.The washing recycling line is widely used in waste plastic recycling,processing PET bottles into rPET flakes.These plastic are suitable for produing the new PET bottles which meet the FDA.The Output of above recycling line ranges from 150kg/h to 1200kg/h,we can also manufacture the customized product according to users' requirement.

Suitable Products:

Suitable Products of Food Safe B2B Recycling Machine

Food Grade B2B PET Bottle Washing Line Paramenters

Model | Capacity | Motor Power | Equipment footprint |

PET10 | 1000kg/h | 220KW | 250㎡ |

PET20 | 2000kg/h | 260KW | 350 ㎡ |

PET30 | 3000kg/h | 380KW | 500 ㎡ |

PET40 | 4000kg/h | 500KW | 700 ㎡ |

Product Details:

Label Remover Machine

Function: The machine can remove above 90% labels for both common and compressed bottle without flakes waste and no water consumption.

Motor power: 15KW

Suction fan power: 5.5KW

Rotary blade : 42pcs ( teeth 378pcs )

Fixed blade : 45sets * 4 = 180pcs ( teeth 1080pcs )

Plastic Crusher Machine

This machine can divide large-size raw materials into relatively uniform small-size raw materials through its function of crushing,processing the PET bottle into small flakes.

Product Display:

B2B Food Grade Cleaning System