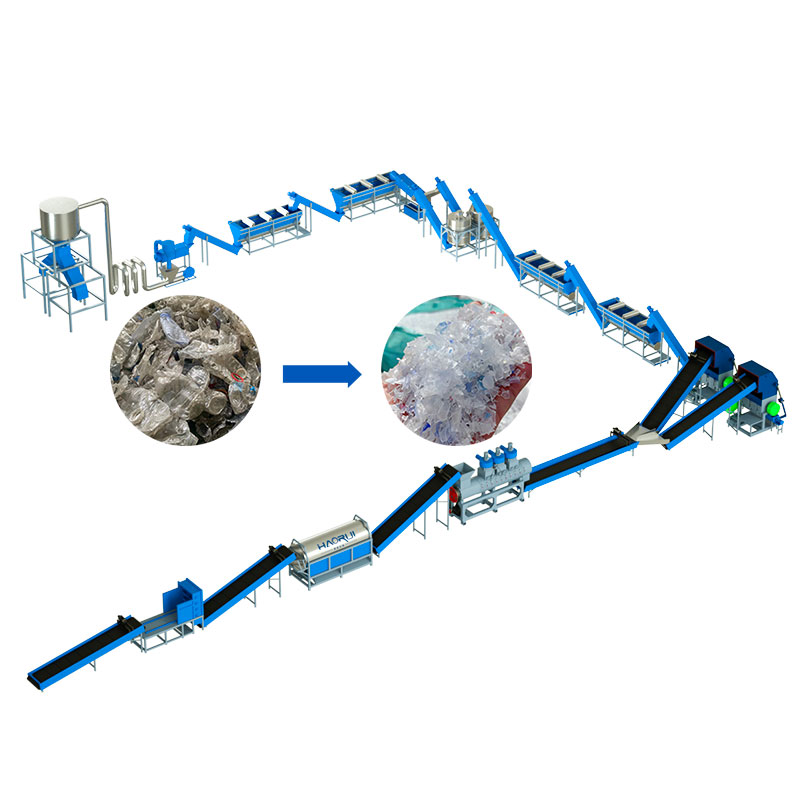

Product Features of Pet Bottle Washing Line

- Capacity Range: The HAORUI PET Bottle Washing Line is available in various models to cater to different production needs, with capacities ranging from 500kg/h to 7000kg/h.

- Grade Options: The machine is capable of producing both food grade and fibre grade PET flakes, ensuring versatility in the end products.

- Customization: Each machine is tailored to the customer's specific requirements, ensuring the most suitable product specifications for their unique situation.

- Certifications: HAORUI holds TUV, CE, and SGS certifications, along with 13 patents, reflecting the company's dedication to quality and innovation.

Product Advantages of Pet Bottle Washing Line

1. Integrated Manufacturing: The entire production and manufacturing process is completed in-house, allowing for effective control over quality and delivery times.

2. Professional Design: With in-house PET flake production, HAORUI's machine design is more professional and better suited for PET flake processing.

3. Energy and Water Efficiency: The 4000KG/H Fibre Grade PET Bottle Crushing & Washing Line operates with an energy consumption of 600KW/H and a water consumption of 4TONS/H, which can be recycled.

4. Quality Assurance: HAORUI insists on a "quality is first" approach, with rigorous inspections post-production, leading to a global sales network and popularity in the domestic market.

5. Technical Expertise: Over 100 technicians and a 9-person R&D team with over 30 years of experience ensure that HAORUI's machine design is unique and meets OEM & ODM requirements.

Additional Highlights of Pet Bottle Washing Line

- Raw Material to Finished Product: The process includes stages from raw materials to cutting, shearing, welding, machining, bending, assembling, painting, and finally, the dispatch of finished products.

- Global Reach: HAORUI has assisted over 40 clients across Vietnam, Thailand, Laos, Cambodia, Myanmar, India, Saudi Arabia, USA, Nigeria, Ghana, Kenya, Algeria, South Africa, and Turkey, showcasing its global impact.

- Infrastructure: The company boasts a substantial workforce of over 300 employees and an annual sales figure exceeding USD 10 million, with 30% of production being exported.

- After-Sales Support: HAORUI offers a 1-year warranty on its machines and provides free formulation for chemical detergents used in the washing process.

Conclusion of Pet Bottle Washing Line

The HAORUI PET Bottle Washing Line is more than just a machine; it's a comprehensive solution for PET bottle recycling, designed to optimize efficiency, reduce environmental impact, and deliver a high-quality end product. With a global footprint and a commitment to excellence, HAORUI is a partner you can信赖 (trust) for all your PET recycling needs.

For more information, visit our website: [HAORUI Machinery](http://haoruijixic.en.alibaba.com)