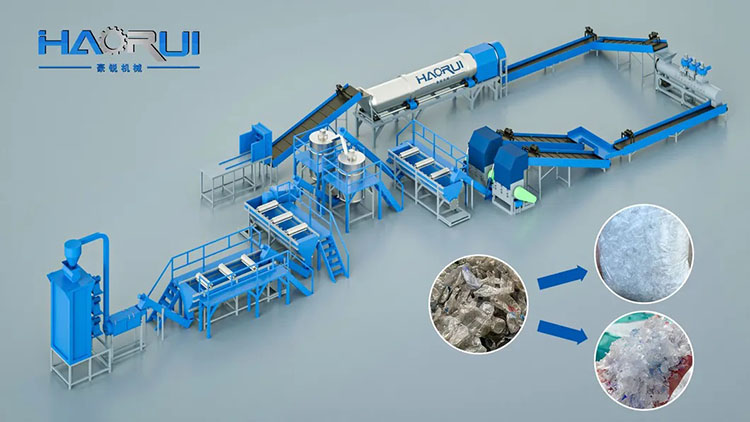

Functions of PET Sheet & Bottle Washing Line

A sheet grade pet bottle flakes washing line is designed to wash and reprocess used PET bottles into clean flakes for new products like bottles,sheets,or fibers by removing contaminants (labels,caps,dirt, glue),shredding these bottles,and then washing and drying them thoroughly.

Equipments of PET Sheet & Bottle Washing Line

The sheet level pet bottles recycling line uses a sequence of machine and equipment,including debaler,trommel screen,conveyor,label remover machine,plastic crusher machine,sink-float tanks,hot washer with detergents,friction washer,dewatering machine,and drying system,sorting (color/polymer) and packaging for high-quality, food-grade recycled material.

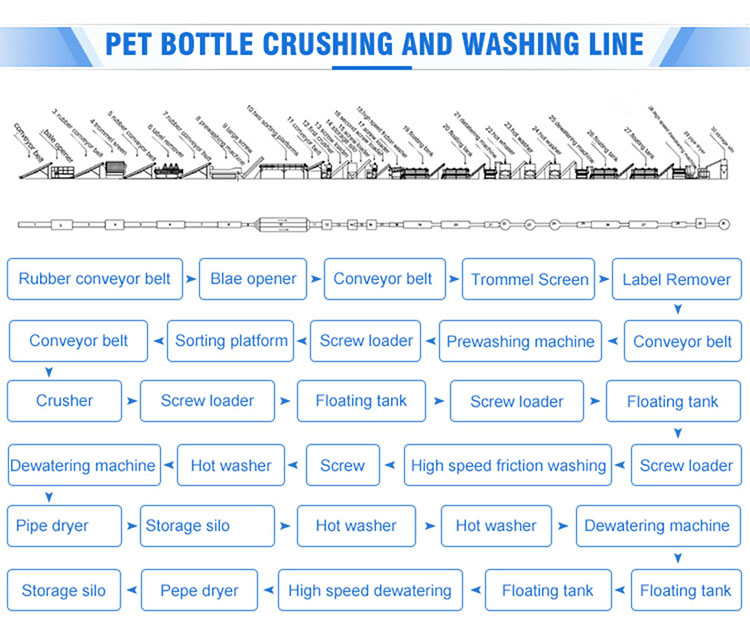

Process of PET Sheet & Bottle Washing Line

This sheet level pet washing line handles a series of multi-stage process,involving bale-opening & sorting,crushing,pre-washing,hot washing with detergents,high speed friction washing,density separation,rinsing,and drying.

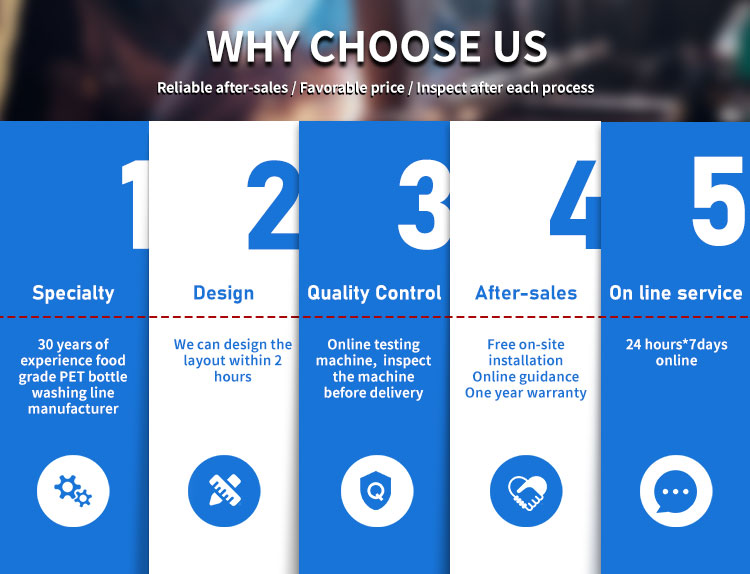

Features of PET Sheet & Bottle Washing Line

Our sheet grade pet bottle flakes machine is characterized by high capacity,adaptability for mixed materials,impurity removal (labels,caps,dirt),and energy-efficient drying,ensuring quality feedstock for downstream applications.

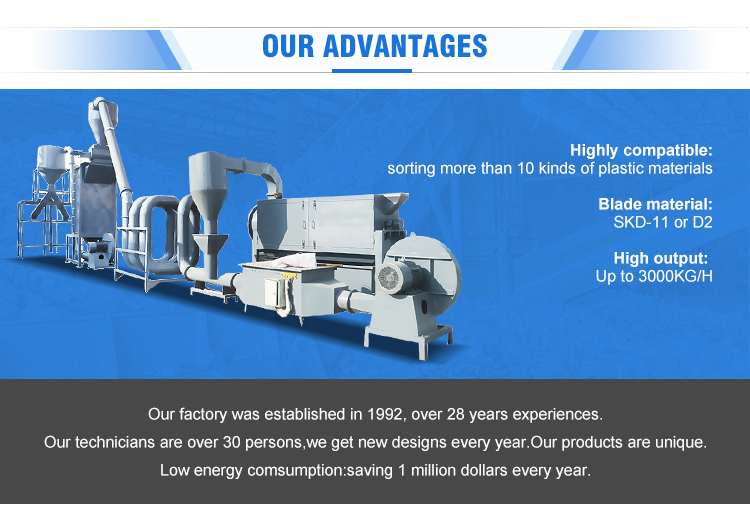

Advantages of PET Sheet & Bottle Washing Line

Above plastic sheet recycling equipment offers major advantages,involving reducing landfill waste,conserving resources,reduced the need for virgin petroleum,and enabling high-quality recycling for new products like fiber,packaging,or even new bottles,supporting a circular economy.

Applications of PET Sheet & Bottle Washing Line

It is primarily used in turning post-consumer PET bottles into clean,pure rPET (recycled PET) flakes.These flakes are used to manufacture new PET bottles (bottle-to-bottle),PET sheets for packaging,polyester fibers,textiles,and other products.