Functions of PET Sheet Bottle Washing Line

A sheet grade PET bottle washing recycling line is capable of turning various types of post consumer PET bottles into recyclable PET bottle pieces effectively through a series of steps such as crushing,cleaning,bottle cap label separating,drying and packaging.

Euqipments of PET Sheet Bottle Washing Line

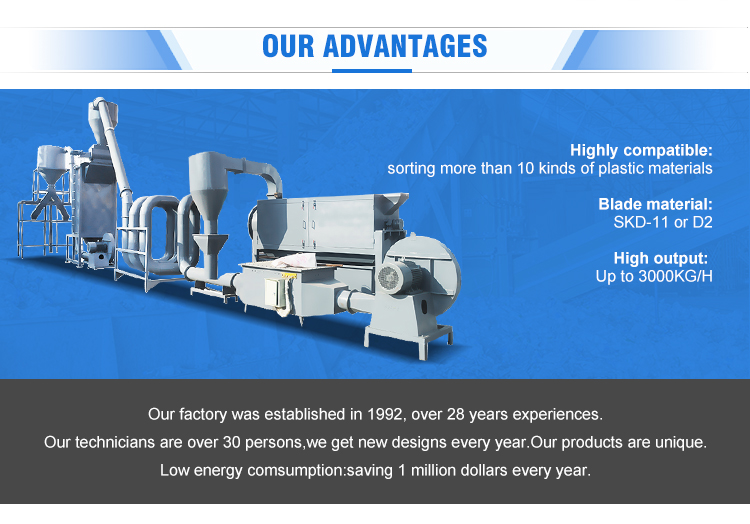

The PET sheet bottle washing line employs a series of interconnected machine and equipment,including bale opener,screw loader, trommel screen,pre-washer,conveyor belt,PET bottle label remover machine,sorting platform,plastic crusher machine,horizontal packing auger,floating tank,dewatering machine,hot washer,high speed friction washing machine,wind conveyor,pipe dryer,label separation,silo storage and electric panel to handle a series of multi stage process components as follows.

Process of PET Sheet Bottle Washing Line

This sheet grade PET bottle recycling machine uses a series of multiple stages process components,involving bale opening,feeding,screening,pre-washing,label removing,sorting,crushing,multiple stages washing process(hot washing,and high speed friction washing),drying,label separating to output clean,dry and high quality recycled PET flakes that moisture content less than 1% for resue in making new PET plastic sheet.

Features of PET Sheet Bottle Washing Line

Our sheet bottle recycling machine offers several features,involving high automation,high efficiency,low energy consumption,easy to disassembly.These features provide the benifits as follows:

High Automation:

High automation boosts production capacity by enabling continuous processing,lowers labor and energy costs through reduced manual intervention and more efficient resource use,and improves product purity by ensuring consistent and precise cleaning processes.

High Efficiency:

High efficiency results in higher throughput,reduced energy and water consumption,and lower labor costs.

Low Energy Consumption:

It makes the recycling process more cost-effective and sustainable,that is crucial for meeting environmental goals and creating a circular economy by turning plastic waste into high-quality, reusable materials.

Easy to Disassembly:

It offers benefits such as simplified and faster maintenance,reduced downtime,improved cleaning efficiency,enabling upgrade or components replacment more easily.