Functions of Plastic Crusher Machine

A industrial plastic bottle shredder is capable of reducing the size of plastic waste by shredding it into smaller pieces or granules,making them easier to handle,transport,and recycle.

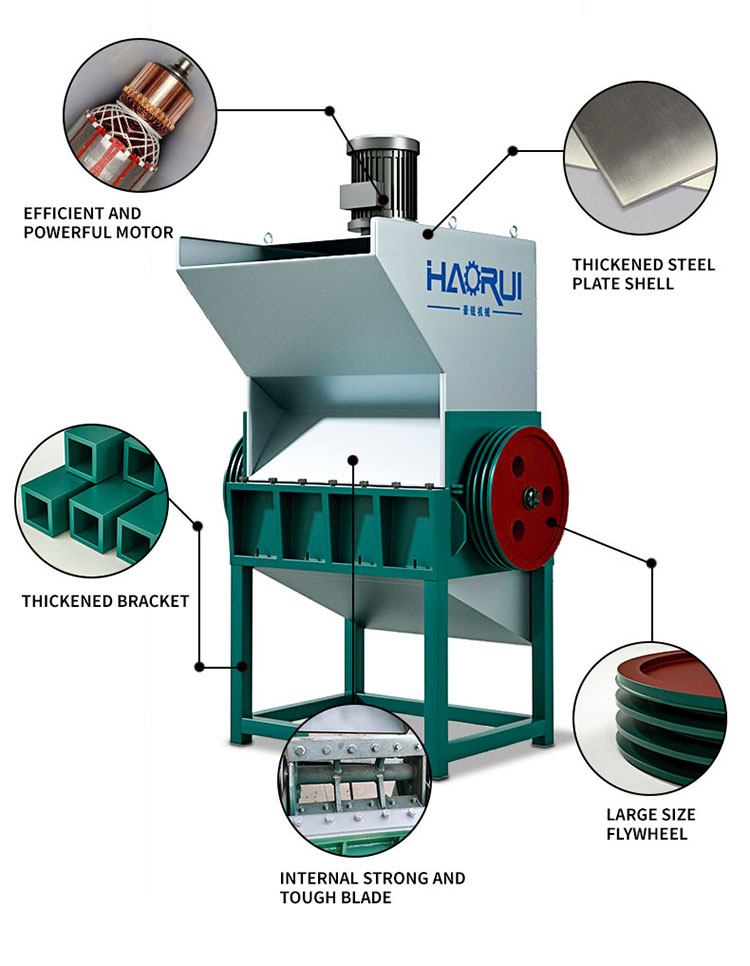

Components of Plastic Crusher Machine

The plastic shredding equipment is composed of a series of interconnected components,including a housing,feed hopper,rotating and fixed blades within a crushing chamber,a motor and transmission system,a screen mesh,discharge port,and the base and frame.

Process of Plastic Crusher Machine

This plastic crushing machine handles a series of process,including feeding the material into the hopper,crushing it into smaller pieces using high-speed rotating blades,and then screening the fragments to ensure uniform size before discharging them for further recycling.

Features of Plastic Crusher Machine

Our PET bottle crusher machine is characterized by a rugged structure,durable blades for different plastic types,a crushing chamber with a screen for determining the output size,adjustable blades for different types of plastic,auto-reverse functionality,and easy-to-disassemble design for ease of maintenance.

Advantages of Plastic Crusher Machine

Above bottle crusher machine offer advantages like reduced disposal costs and cost savings through lower transportation expenses by reducing waste landfill,and increased the efficiency of recycling operations,providing environmentally beneficial by decreasing pollution,conserving resources,and lowering carbon footprints.

Application of Plastic Crusher Machine

The plastic bottle crushing system is used in breaking down plastic waste into smaller,more manageable pieces for reprocessing and reuse.The crushed plastic can be directly fed into extruders or injection molding machines,or it can be pelletized for further processing.