Competive Price 500kg/h PET Sheet & Bottle Washing Line for Plastic Recycling

Product Description:

The PET sheet & bottle washing line consists of a series of machine and equipment including belt conveyor,pre-washer,label remover,crusher,floating tank,hot washer&friction washer,zigzag label separator,intelligent control system.The introduction of them is as follows:

Belt Conveyor: Before the PET sheet & bottle washing line will process and recycle the plastic film, raffia, filament, woven bag, bottles, etc,belt conveyor is responsible for transporting them into pre-washer.

Pre-washer:It is responsible for pre-washing bottle,removing small size impurity,decreasing the working pressure for downstream machines like label remover that is used in seperating small impurities such as, bottle labels, soil, sand, etc.

Label Remover:The label remover machine is responsible for seperating small impurities like bottle labels and so on.

Crusher:It is reffered as to plastic crusher machine that is used for crushing material into small sizes,cleaning material with water and cooling blades during crushing.

Floating Tank: It has the function of making remaining label, caps and other impurity float and separate from PET flakes.

Hot Washer&Friction Washer: Hot washer refers to washing the bottle flakes by steam or hot water and friction washer can clean the bottle flakes more fully.

Zigzag Label Separator: The vertical Z-shaped zigzag air separator can accurately separate the labels and impurities from the bottle flakes.

Intelligent Control System:There are two option of power control that the intelligent control system with CE/ROHS standard supplies to you. 1. For electric control of the whole line. 2. Main electrical units: WEG, Siemens, Schneider, ABB, DELTA, Omron, RKC, etc.

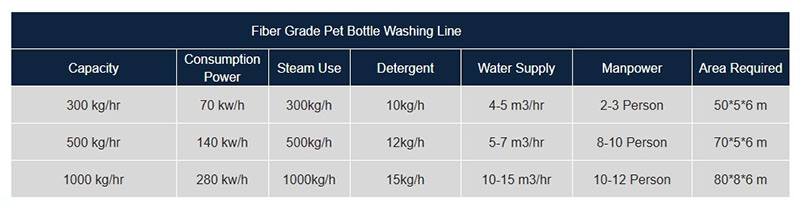

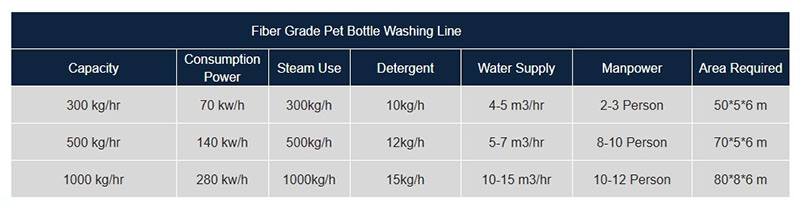

Product Specifications:

Specifications for PET Sheet & Bottle Cleaning System

Aplicable Materials:

Aplicable Materials for Sheet & Bottle Recycling Machine

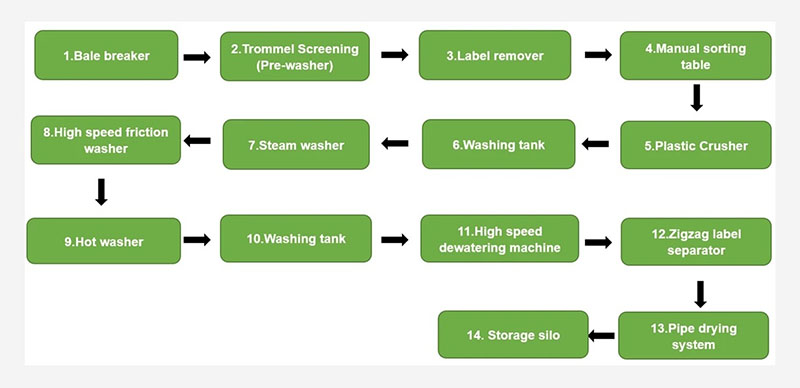

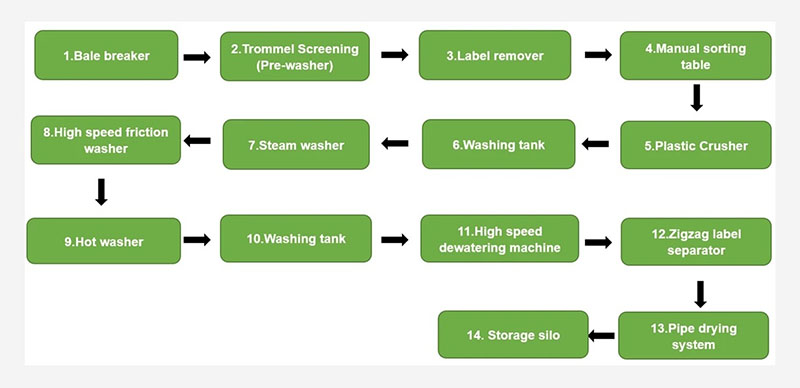

Process Workflow:

Process Workflow of Plastic Sheet Recycling Equipment