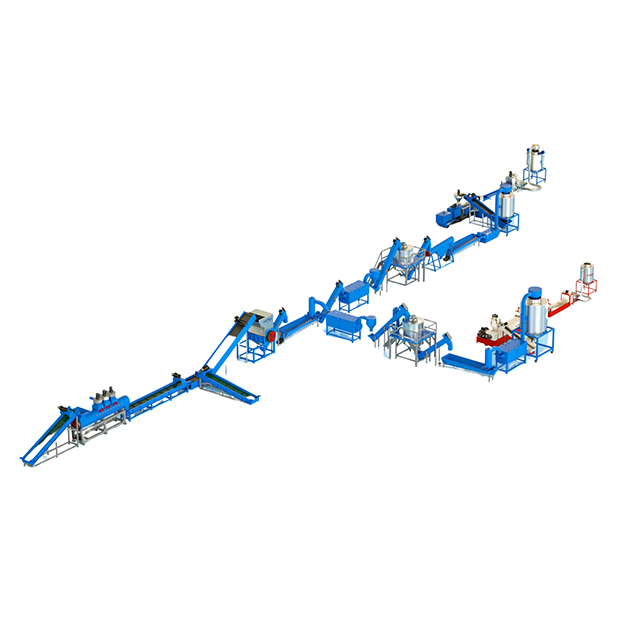

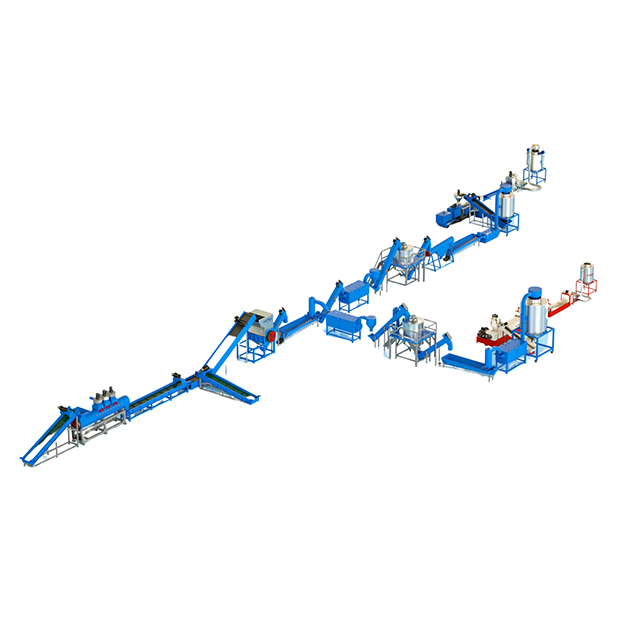

Long Service Life 3000kg/h Food grade b2b PET Bottle Washing Recycling Line

Description for Food Safe B2B Recycling Machine:

Haorui food grade B2B PET bottle washing recycling line can be operated automatically,not only can improve the productivity,but also can save a quantity of labor.The food grade b2b pet bottle washing line cost features high efficiency,low power consumption,easily operated and competive price.In a word,it processes performance price ratio.

About Our Factory:

As one of the China OEM,our PET bottle recycling plant has the whole components of plastic recycling process,not only can manufactures the complete food grade B2B PET bottle washing line,but also can making the post consumed PET bottles into new food grade PET bottles.

No. | ItEM | DESCRIPTION |

1. | Bale Breaker | Break up the compressed bottle bale |

2. | Conveyor Belt | Transport bottles to label remover |

3. | Label Remover | Remove the labels on the bottle (label removing cleanliness higher than 98%) |

4. | Manual Sorting Platform | According to workers' height, supply a suitable plate to pick out the left labels or some other impurities |

5. | Conveyor Belt | Transport the bottles into crusher |

6. | Crusher | Crush the bottles with water |

7. | Screw Loader | Conveying the flakes into floating washing tank |

8. | Floating Rinsing Washing Tank | Remove paper scraps, sand, labels out of flakes owing to different buoyancy in water |

9. | Screw Loader | Conveying the flakes into hot washer |

10. | Hot Washer | High temperature stirring washing with caustic soda. Water can be heated by steam or electric or coal around 90 degress |

11. | Screw Loader | Conveying the flakes into friction cleaner |

12. | Friction Cleaner | Scrubbing the flakes at hgih speed with water |

13. | Screw Loader | Conveying the flakes into floating washing tank |

14. | Floating Rinsing Washing Tank | Remove paper scraps, sand, labels out of flakes owing to different buoyancy in water |

15. | Screw Loader | Conveying the flakes into floating dewatering machine |

16. | Dewatering Machine | High speed centrifugal drying. Horizontal or Vertical dewatering machine |

17. | Wind Drier | Electric heating wind drying. |

18. | Label Flakes Separator | The last left impurities will be separated out of flakes by the blower fan |

19. | Storage Silo | Store the final material |

20. | Electrical Control Cabinet | Control the whole line |

Product Display:

Food Safe B2B Recycling Machine