A PET sheet bottle washing line is specialized in recycling used PET bottles into clean,high-quality flakes suitable for manufacturing sheet-grade PET.

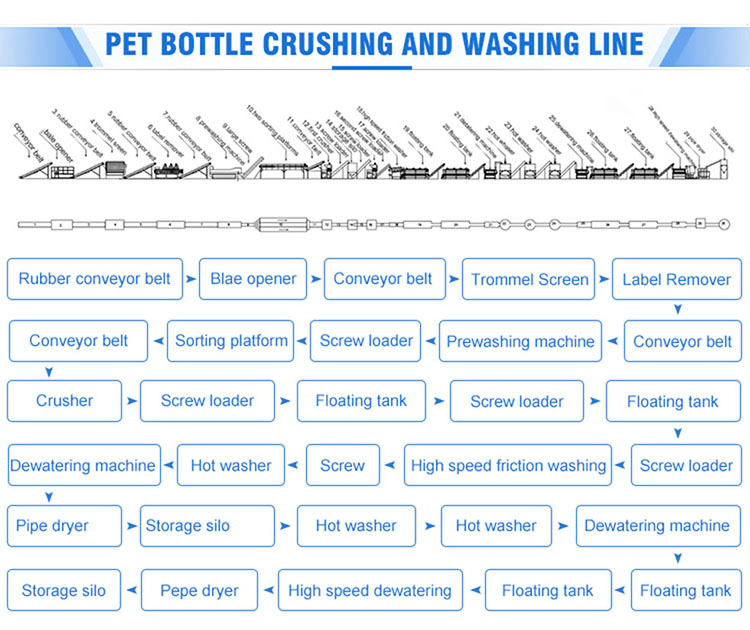

The plastic sheet recycling equipment consists of a series of interconnected machine and equipment.The functions and usages of them are listed as follows:

Key Components & Process

Label & Cap Removal

Advanced separation systems (e.g.,air classifiers,label remover machine) eliminate plastic labels and caps (usually HDPE/PP) using mechanical friction,suction,or flotation.

Pre-Washing

PET bottles are rinsed with water or steam to remove surface dirt,sand,and light organic residues.

Crushing/Granulation

Bottles are reduced to small flakes (10–15mm) using a wet granulator or plastic crusher machine,which partially cleans the material during size reduction.

Hot Washing

Flakes are soaked in hot alkaline water (70–90°C) with 1–2% caustic soda to dissolve glue,grease,and stubborn residues.

Friction Washing

High-speed friction washing to remove remaining contaminants,ensuring purity.

Flotation/Sink-Float Separation

Water-based separation removes lighter materials (e.g.,PP/PE caps,labels) from denser PET flakes.

Drying

Centrifugal dewatering machine removes bulk water,followed by thermal drying to reduce moisture below 1%.

Final Inspection & Packaging

Flakes undergo quality checks before storage or pelletizing.

Technical Specifications

This PET sheet bottle recycling machine’s technical specifications includes power requirements(280V/380V/480V,3-phase,50/60Hz),material compatibility(PET bottles washing using water,soda,juice containers);some systems handle HDPE/PP caps.

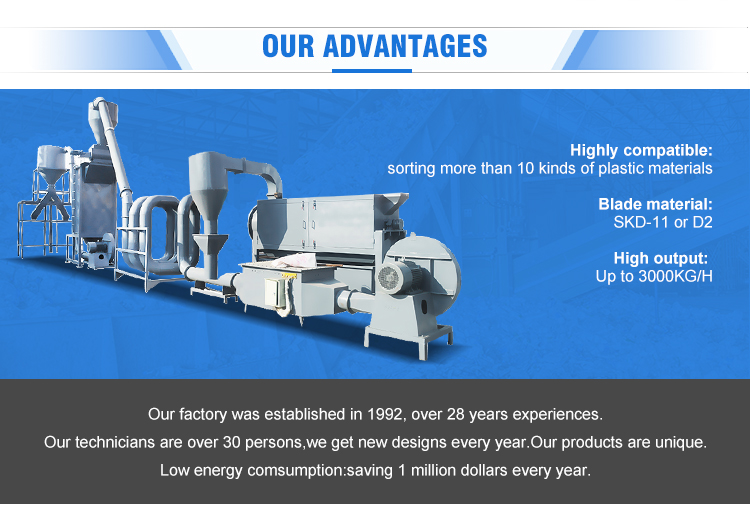

Key Features

Our recycled plastic sheet machine offers numerous features,including configurating durability stainless steel contact parts,rock wool insulation in hot washer for energy efficiency,and automated chemical dosing for consistent cleaning.