Equipments of Food Grade B2B PET Bottle Washing Line

A food grade B2B PET bottle washing recycling line is composed of a series of interconnected machine and equipment,including pre-washing,trommel screen,plastic crusher machine,screw,PET bottles label remover machine,floating tank,high speed friction washer,dewatering machine to produce high quality PET flakes,enabling it to run automatically,promoting work efficiency and producticity,saving labor,and minimizing down time.The functions and usages of these machine and equipment list as follows:

Bale opener:

A bale opener is responsible for opening the PET bales,both vertical and horizontal are available.

Sorting platform:

It is specialized in carrying and transporting PET bottles using the sorting process,while the workers are responsible for picking out the other impurity.

Conveyor belt:

Conveyor belt is designed to carry and transport bottles.

Trommel screen:

Trommel screen is an equipment that can remove the sand,dust,stone and other dirty from the bottles according to the size of them.

Pre-washing system:

It is capable of removing the impurities like the sand,stone,and even mud on the bottles,before the plastic crusher machine handles the process of crushing.This pre-washing is a very important process component to clean the plastic,reduce the production cost and reduce damaging to the following machines like PET bottle label remover machine.

Label remover:

The label remover machine is an equipment to remove the label of the bottles using the unique design quantity and shape of blades with patent certificaiton.

Crusher:

The plastic crusher machine is specialized in crushing plastic materials into flakes with water feeding to reduce friction,preventing wear from the materials.

Screw loader:

Screw loader’s function is to transport the material into next process.

Floating tank:

Floating tank’s function is to rinse PET flakes,automatically separate caps,rings and other floating debris,and effecitively separate varieties of silt and paper scrape.It uses the rinsing process component.

Hot washing tank:

It is used for washing the PET flakes using hot water(with soda and washing chemical) to remove the glue,oil,the final flakes get clean and bright.It handles the hot washing process component.

High speed friction washer:

High speed friction washer is a machine to remove the small sand,label,and other dirty through the process component of high speed friction washing,thus the flakes will be more clean.

Dewatering machine:

It is a drying machine through centrifugally spinning automatically feeding process to dry flakes and discharge one time.

Pipe dryer:

Pipe dryer serves as an another dryer to dry the flakes through hot air.

Label seperator:

Label seperator(Zig Zag Seperator) is a label remover machine to separate the other light material from the PET flakes.

Silo storage:

It’s function is to collect the final flakes.

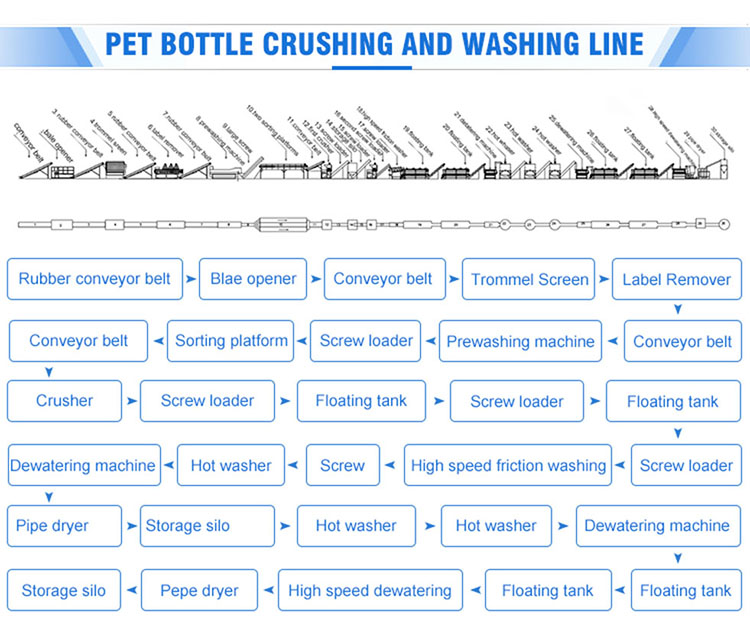

Process of Food Grade B2B PET Bottle Washing Line

The food safe B2B recycling machine uses a series of multiple stages process components,including de-baling,sorting,pre-washing,crushing,hot washing,friction washing,rinsing and drying to manufacture new food-contact items.

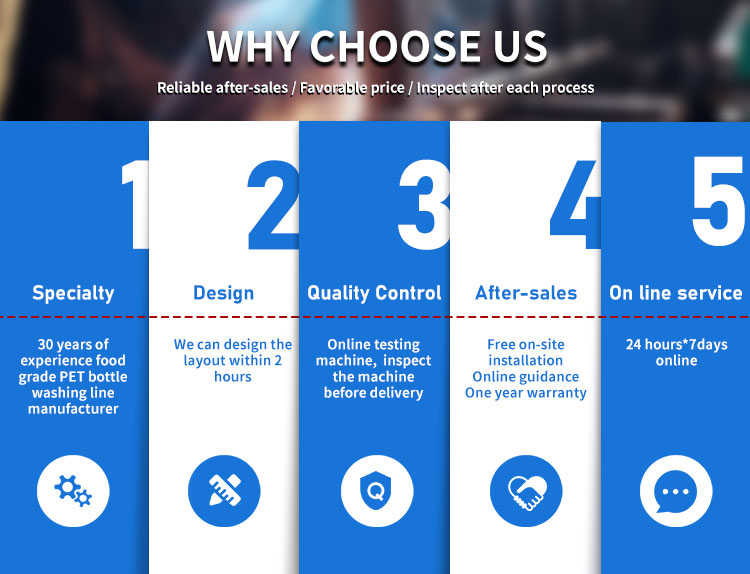

Features of Food Grade B2B PET Bottle Washing Line

Our B2B food grade cleaning system features a series of high automated multi-stages process components,promoting the work efficiency and product,reduced the production cost by using pre-washing system,easy to maintain,cutting with water to reduce wear,esuring the quality of resulting product,using hot washing(with soda and washing chemical) to get clean and bright final flakes,drying with automatic feeding to dry flakes and discharge one time,promoting the processing efficiency,and lowering evergy consumption.