High Capacity 5000kg/h PET Sheet & Bottle Washing Line for Plastic Recycling

Product Description:

Compaired with a single PET sheet washing line and a single PET bottle washing line,a PET sheet & bottle washing line is a PET sheet & bottle washing line is a dual-purpose PET plastic recycling line.This recycling line can transform PET sheets that come from packaging and PET bottles clean, usable PET flakes or granules,readying for the further graunulating process to make new product.The line consists of a series of machine and equipment including bottle pre-washing system&trommel screen,lable remover,crusher,floating tank,hot washer,high speed friction washer,dewatering machine,zig zag label separator.The process components of above line include washing, crushing, drying, and sorting the PET material to remove impurities and labels. The capacities of the PET sheet & bottle recyling machine can be various,the maximum capacity up to 5,000 kg of PET per hour.

Process Details:

1. Crushing/Granulating:

Using a wet or dry PET granulating machine,the PET sheets are first crushed into smaller pieces to make them easier to handle and wash.

Wet granulating need to add water during the crushing process, aiding in cleaning and pre-washing.

The standard grid size for the plastic recycling granulator machine is typically around 12/14mm, according to Chang Woen.

2. Washing:

The smaller pieces that are crushed in the crushing/granulating process is washed to remove dirt, debris, and other contaminants.

This washing process can involve hot or cold water, detergents, and sometimes specialized washing methods including cold waher,hot washer,floating and high speed friction washer.

The washing process involves label separation, cap separation, and other purification techniques.

3. Dehydration and Drying:

Using high-speed air,the drying tubes can reduce the moisture content to below 2%.heat-exchange air drying.Utilizing heat-exchange air drying,the moisture content can also be further reduced to below 0.7%

4. Sorting and Purification:

During the sorting process,the washed and dried PET flakes are then sorted to remove any remaining impurities, including labels, caps, and other non-PET materials.

During the sorting and purification process,optical sorting or manual sorting may be used to ensure high purity of the final product.

5. Further Processing:

The clean PET flakes can be used to manufacture all kinds of products, including new PET bottles, sheets, polyester staple fiber, or further processed into plastic granules.

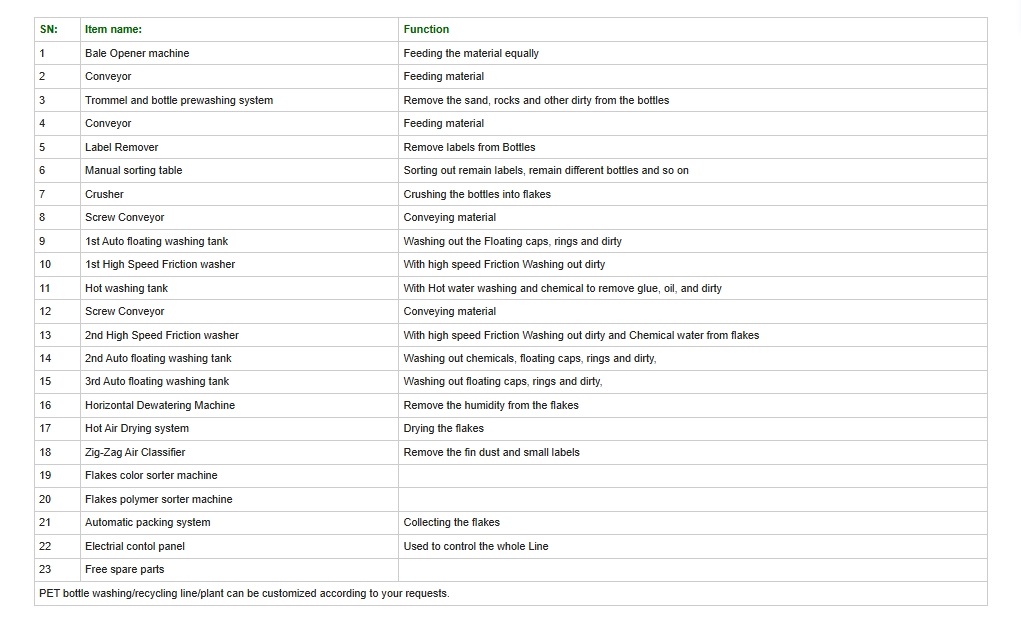

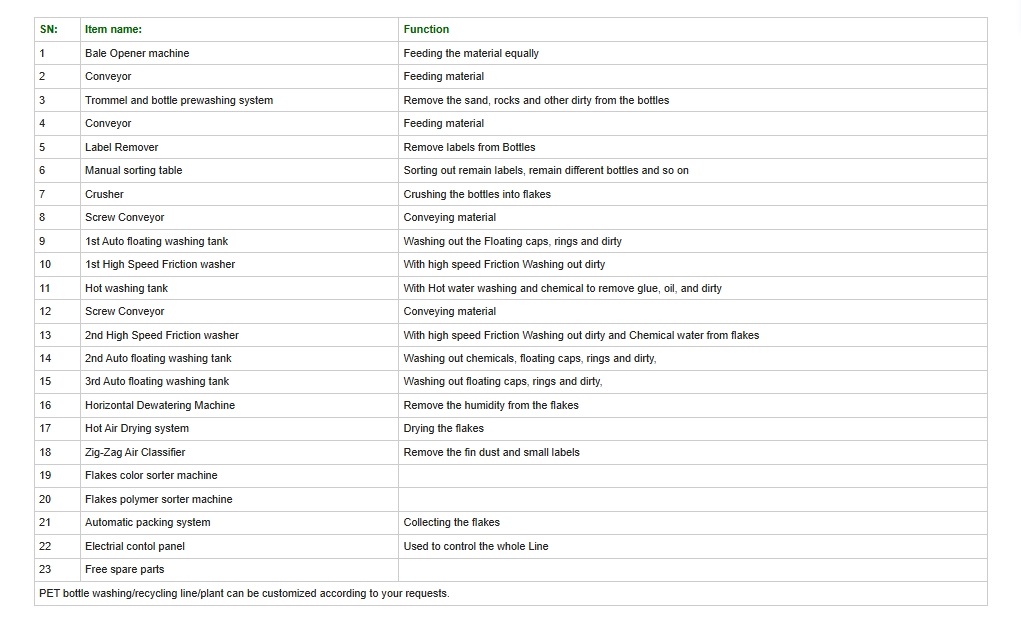

Product Parameters:

Parameters for Sheet & Bottle Cleaning System

Product Display:

PET Bottle Plastic Sheet Recycling Equipment